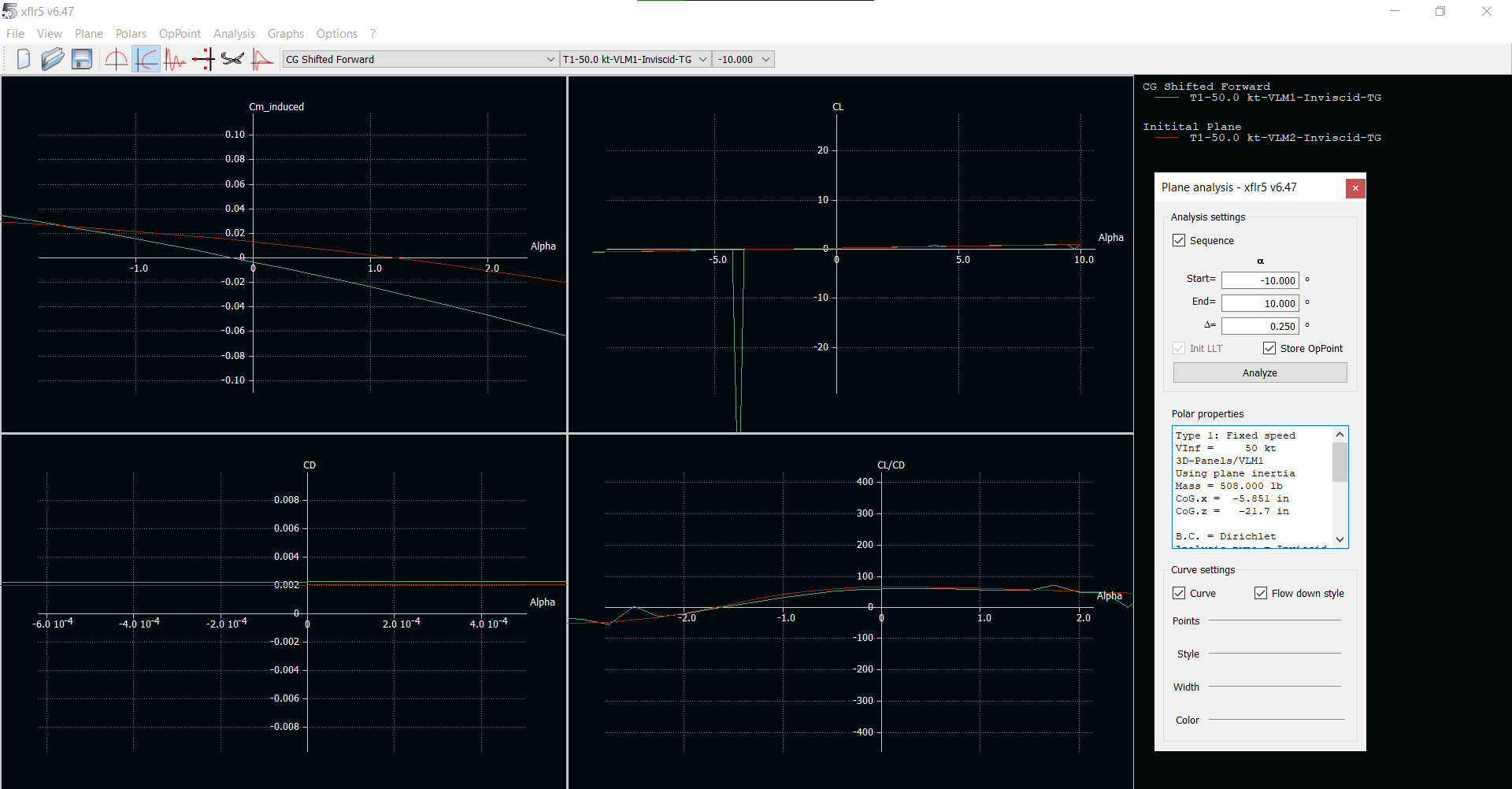

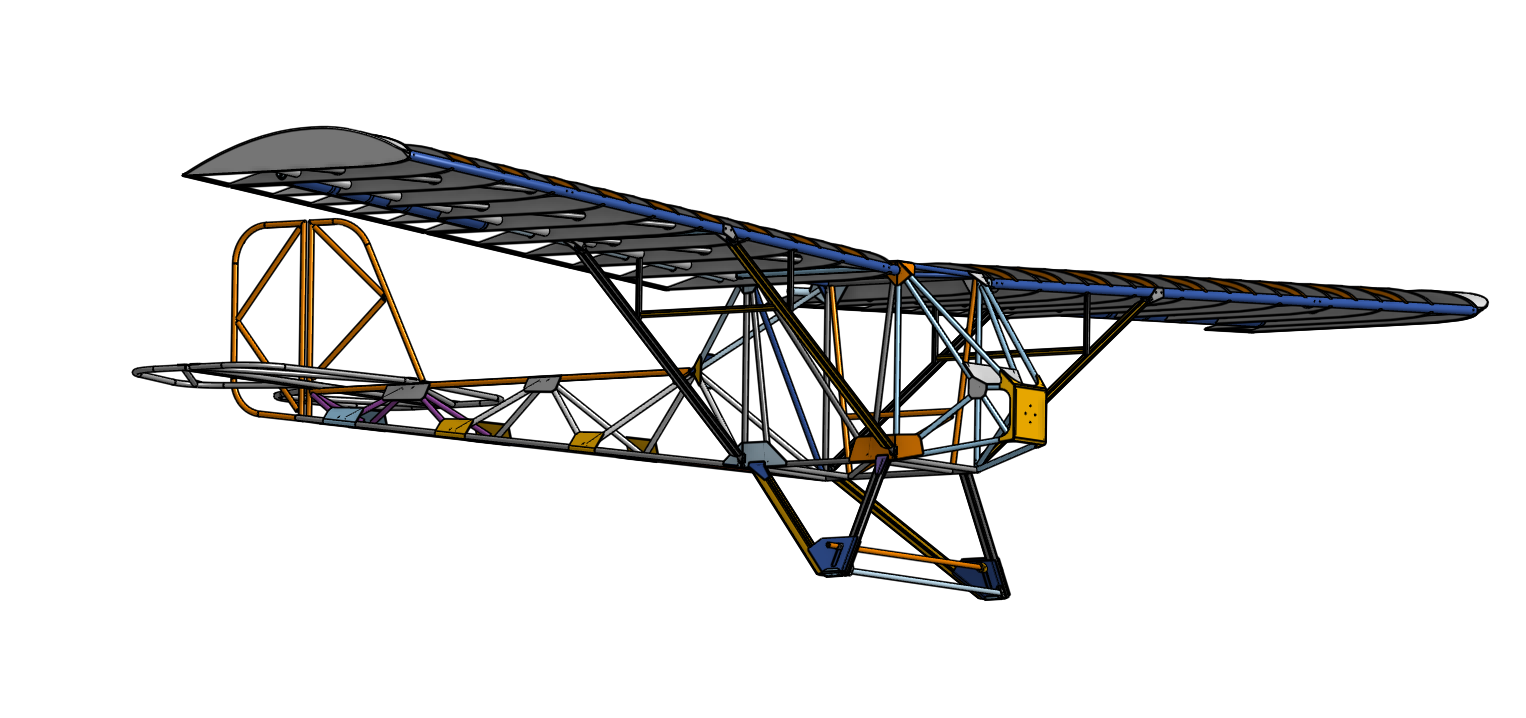

For the past year and a half, I've been working with Flight Club Aerospace, a now 45-high school student team designing and building an FAA part 103 Ultralight Airplane from scratch. I started on the Design team, where I helped design the fuselage, control system, and the wing's attachment to the fuselage. I've ventured far beyond design as well, where I've helped simulate our fluid mechanics through XFLR5 to ensure our static stability and our truss through Fusion and Solidworks to validate our structural integrity. As well, I kick-started our Outreach team to co-create an 8-week summer camp for middle schoolers and have been working with the Finance team. Beyond technical knowledge, as President and former Design co-Captain I've learned an incredible amount about leading a team and creating a fun learning environment where people can freely follow their engineering passions. It's been a very good time - gooooo FCA!

The full ultralight plane designed in Fusion 360!

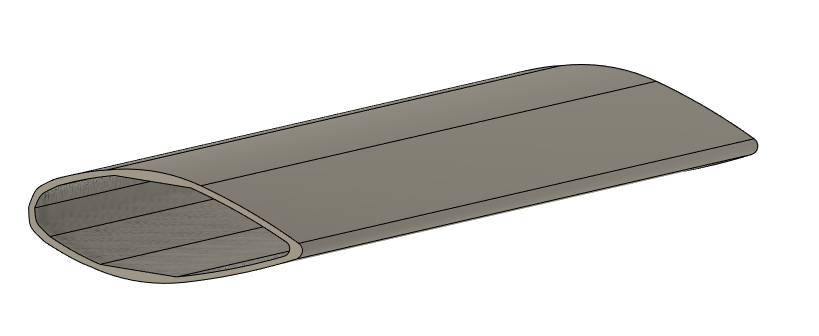

Mostly completed wing - made from XPS foam, epoxy, fiberglass, and aluminum spars/struts/aileron torque tube.

Fabrication Photos

Creating Prototype Ribs

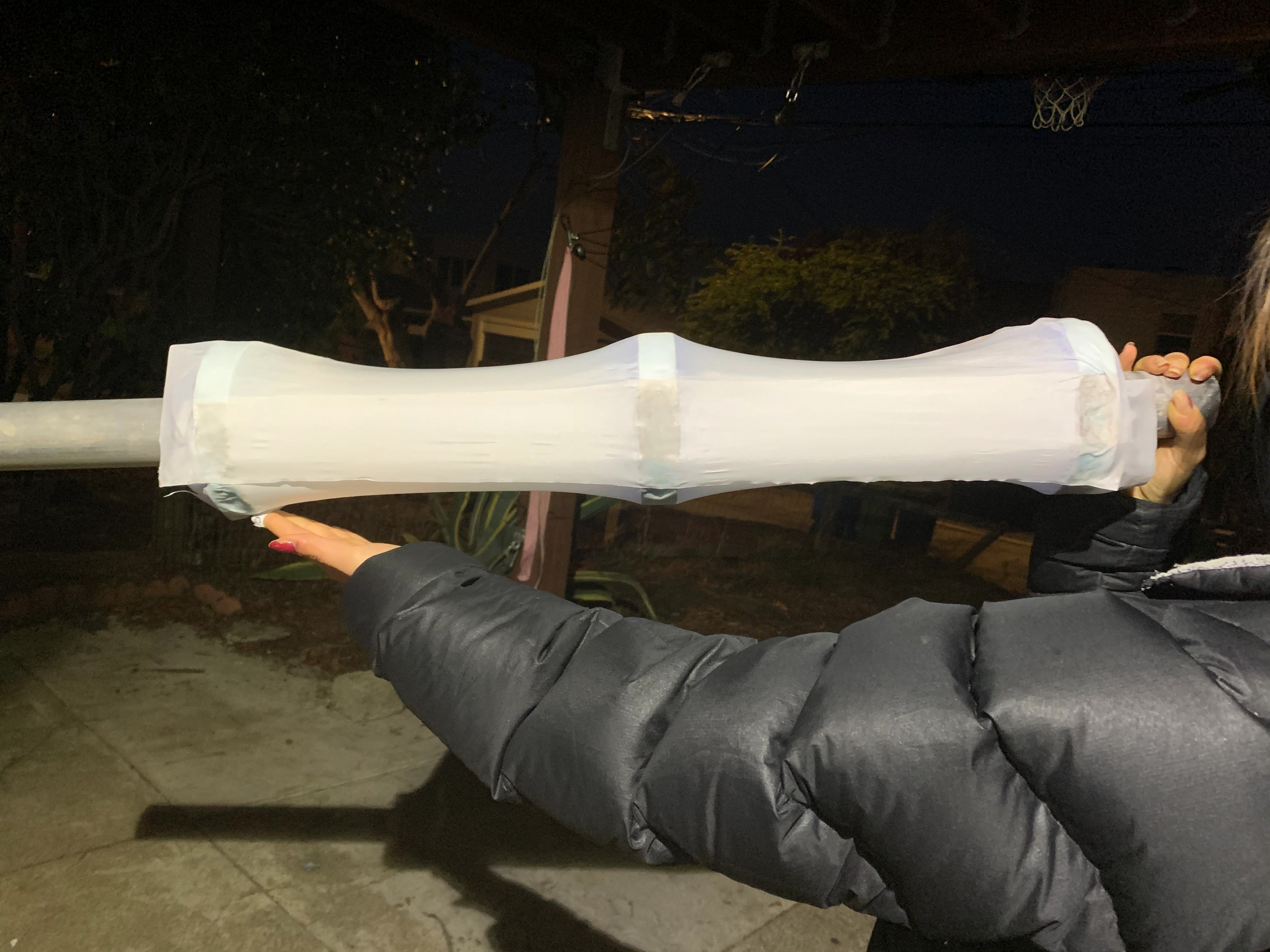

Wing covering prototype

Testing the ribs

Final Ribs Routed out

Routing out the ribs

adding fiberglass to the ribs

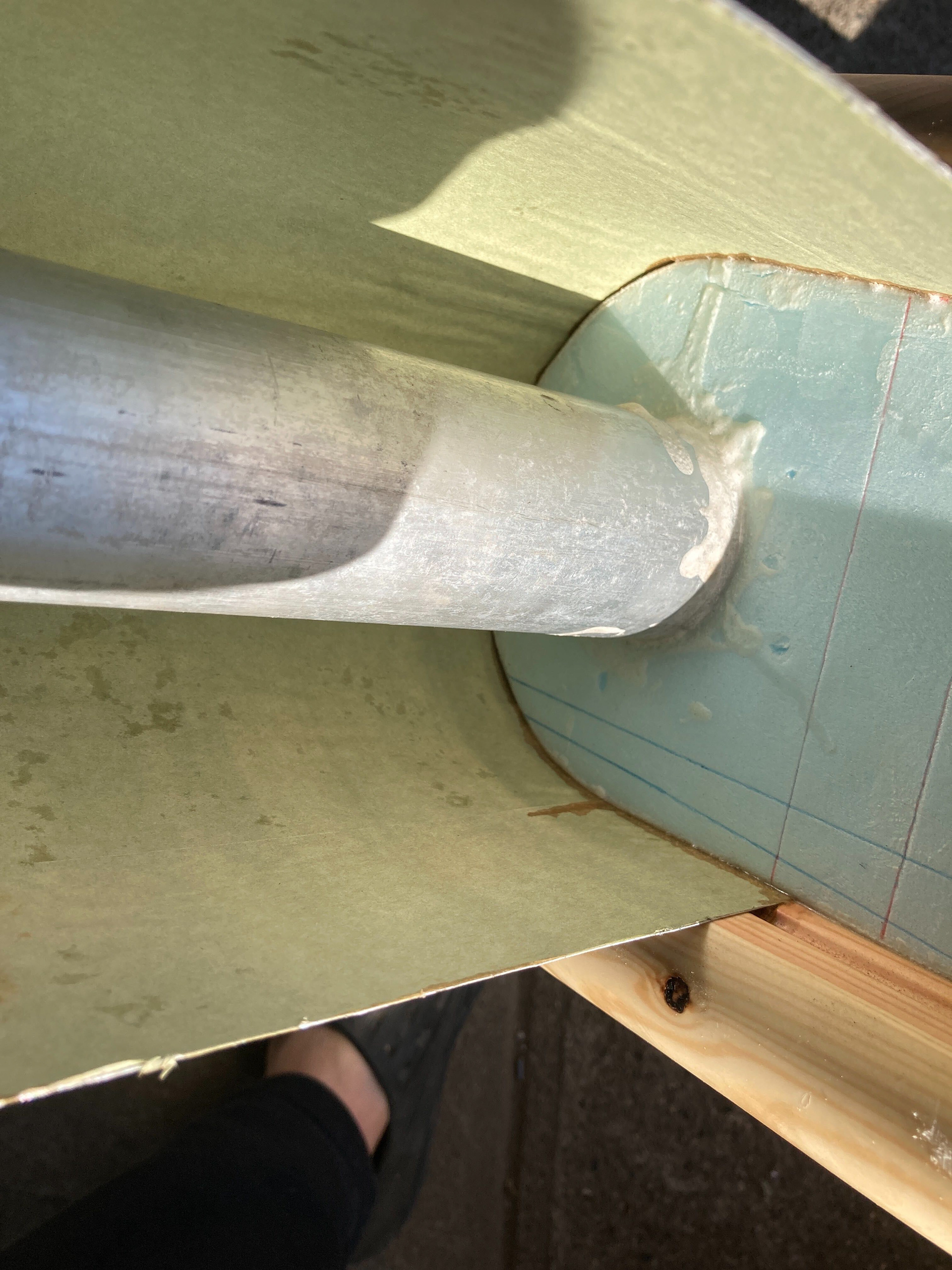

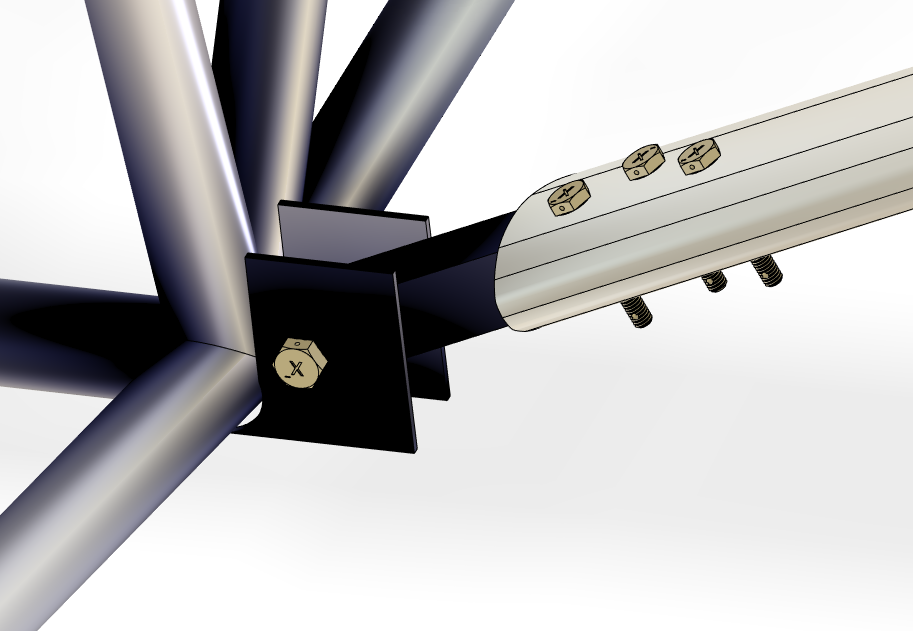

Testing the spar-strut attachment

final wing with leading edge

drilling attachment holes

new spar cap design

creating the spar caps

Creating test cube gusset

Applying epoxy to ribs

Leading edge prototype

Design + Physics Photos

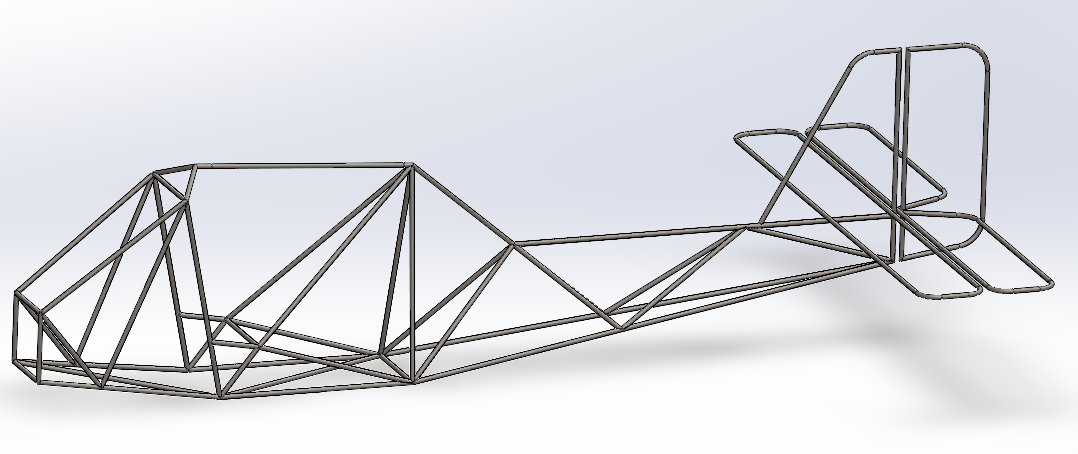

New Design in Solidworks

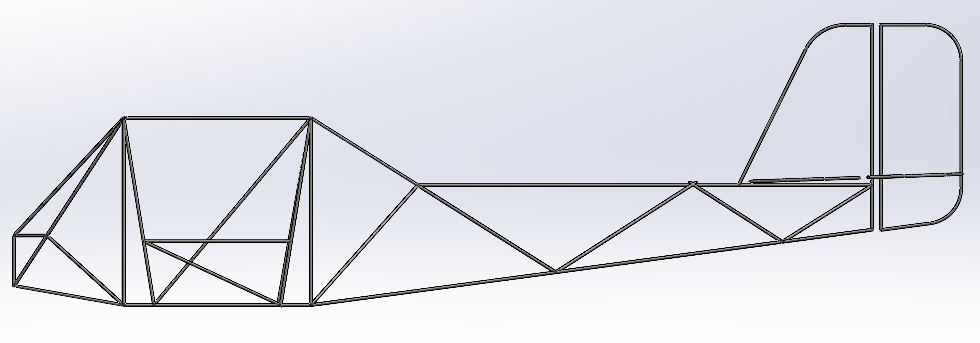

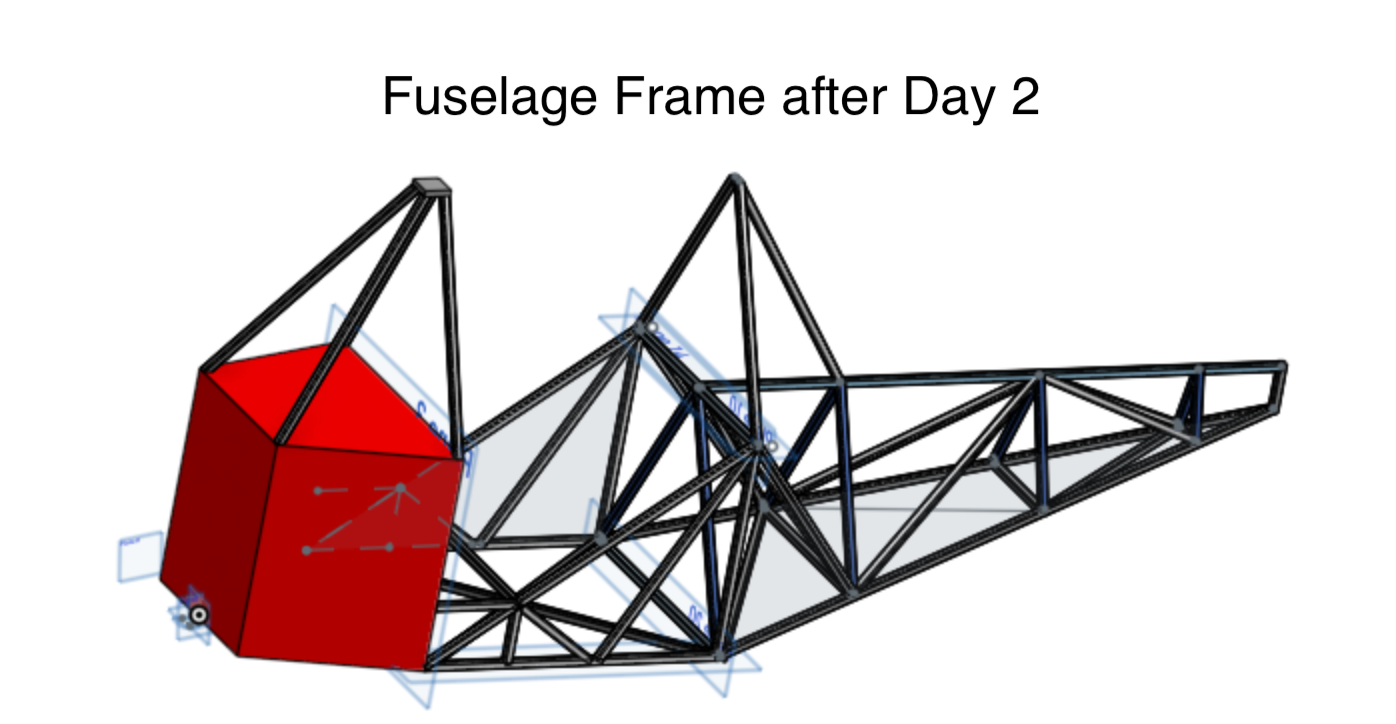

V1 Fuselage

V0 Fuselage

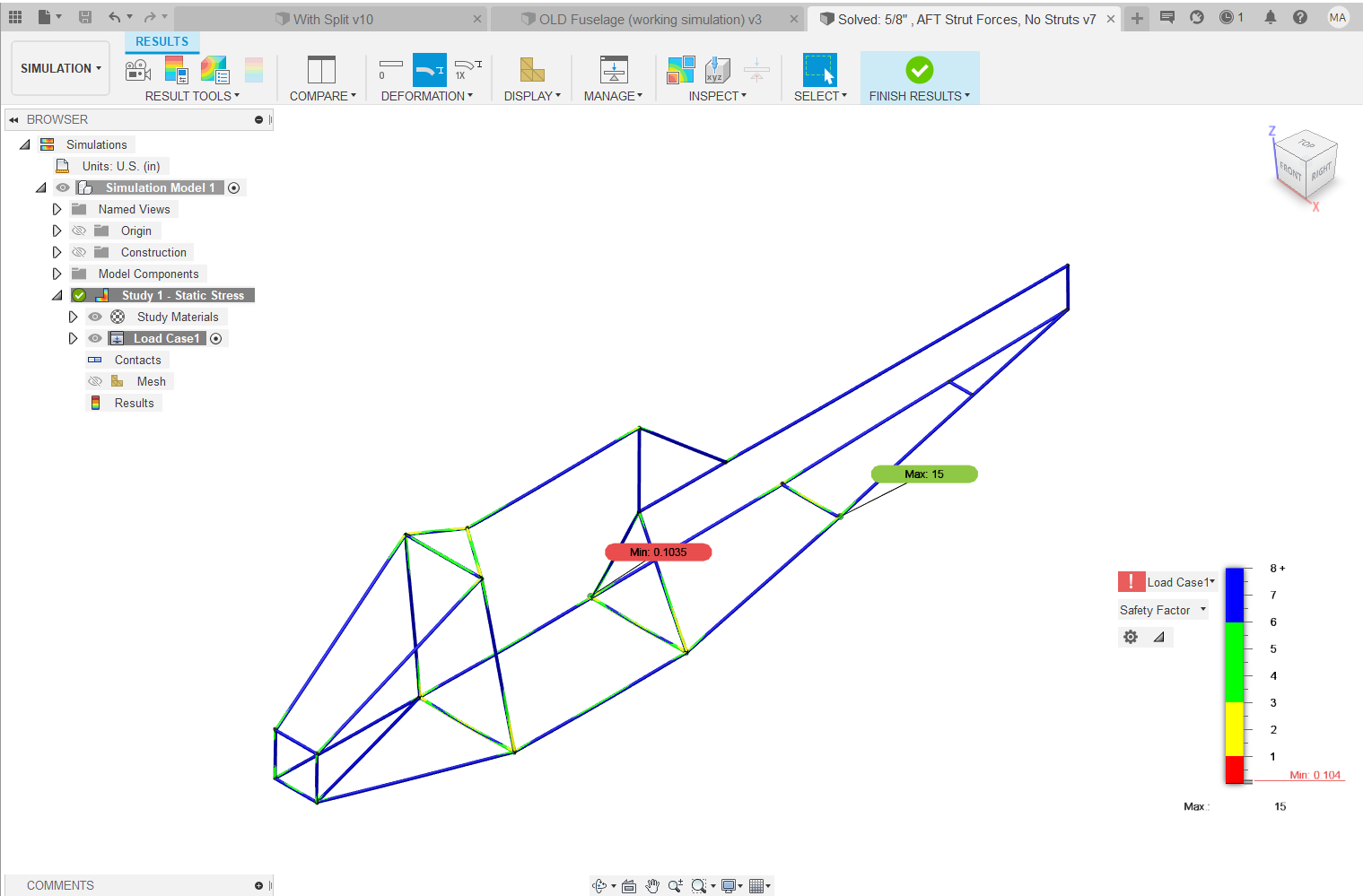

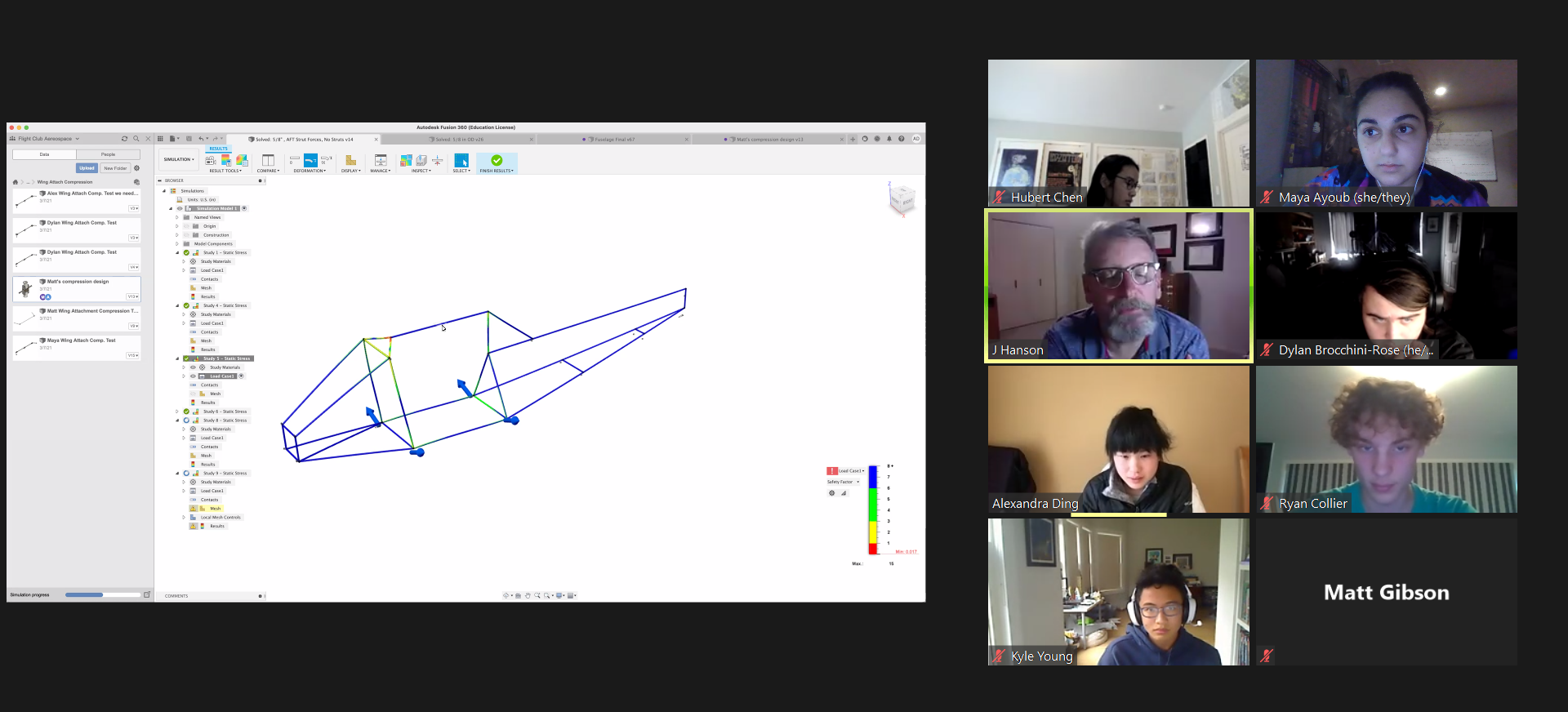

Simulating Fusion

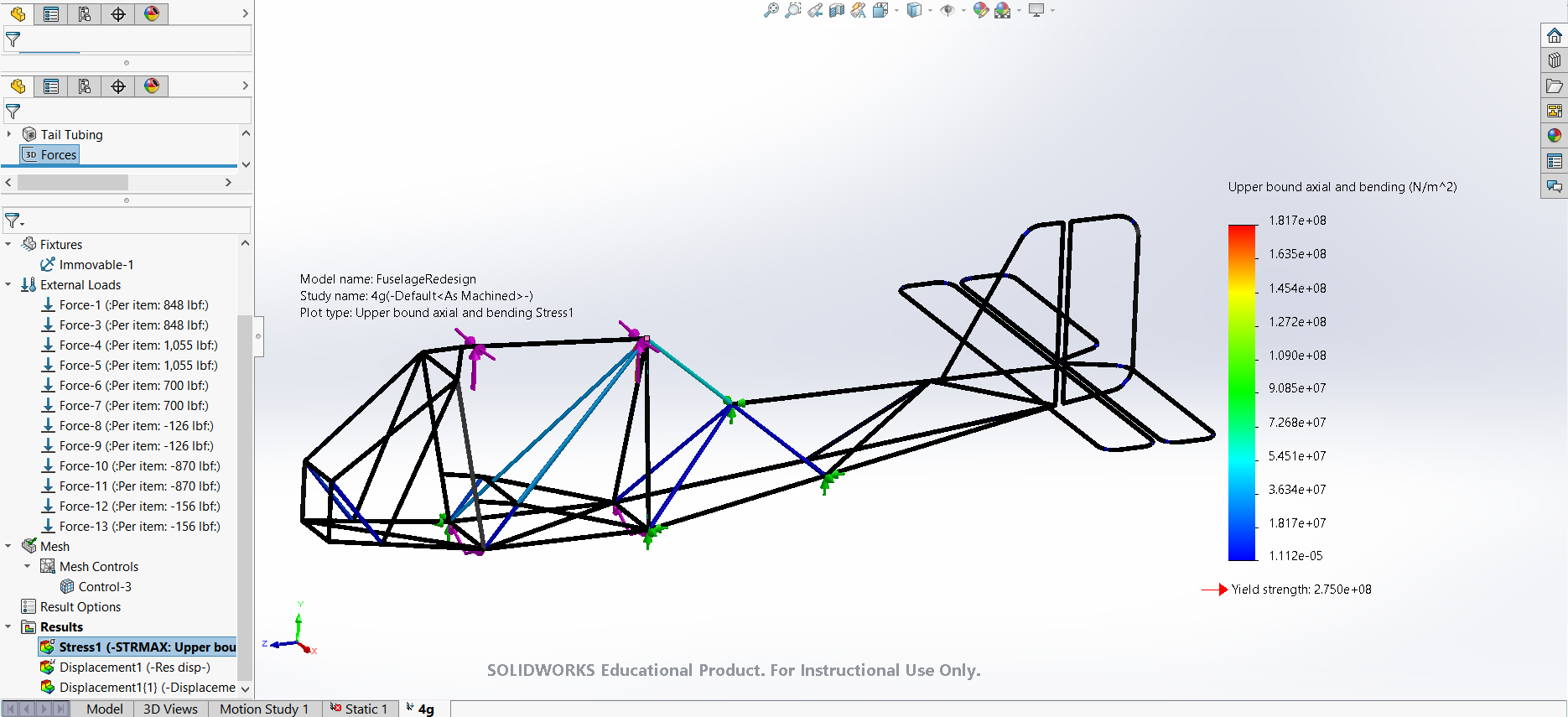

Simulating Fusion 4g

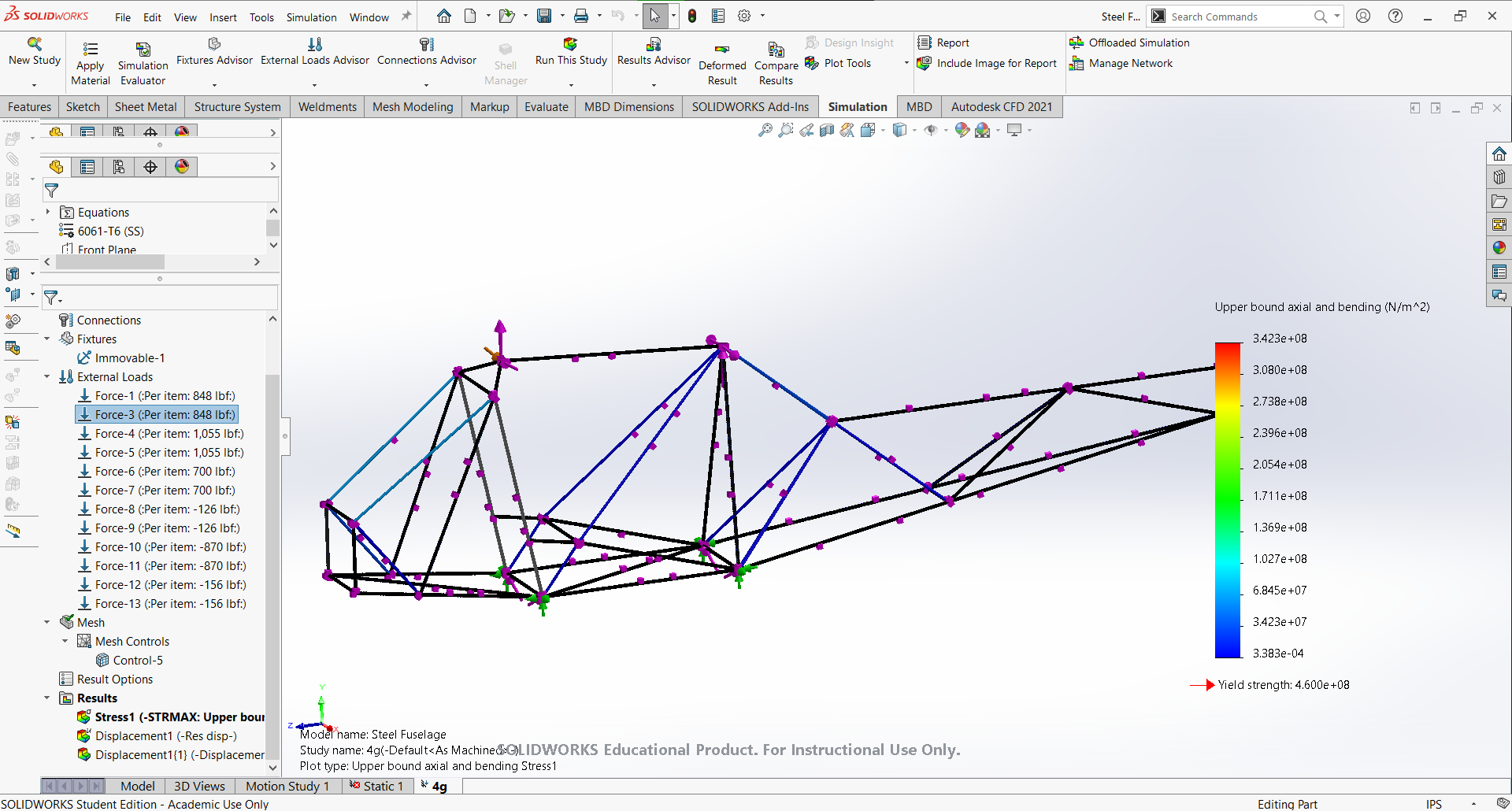

Simulating Steel 4g

Design for the Aileron Bell Crank

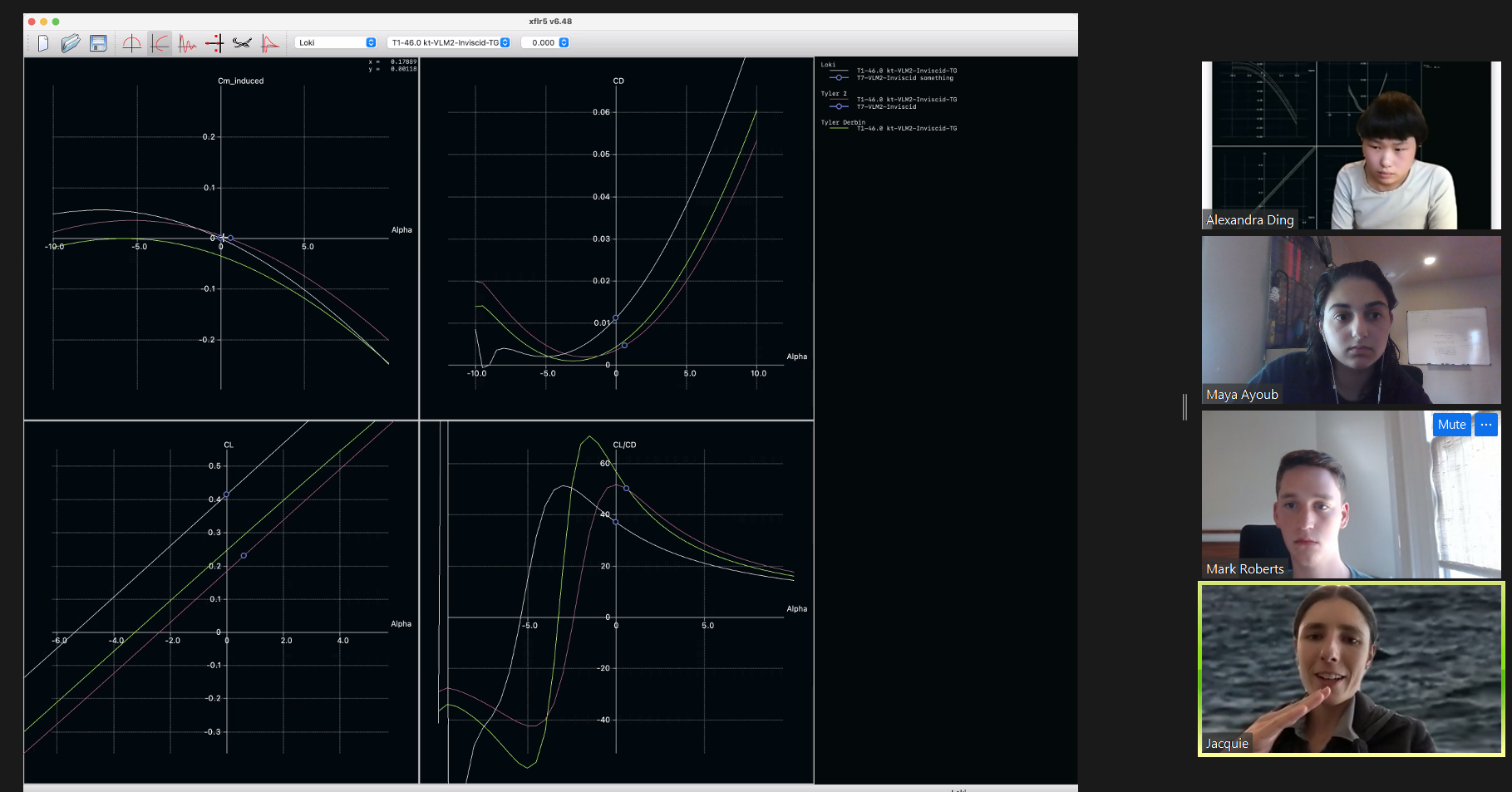

XFLR5 before + after redesign

Old Design Full CAD

Spar-Strut Attachment

Fuselage-Strut Attachment

Strut CAD

:) Photos

Teaching XFLR5

Teaching Fusion Simulation

Beach Day!

Meeting with Elroy Air

October 2021 Team Photo!

Professor Thomas meeting

Professor Shirmohamadi meeting!

Professor Hanson meeting!

FCA Merch Logo